Presse à ferraille

Introduction au Presse à Métaux

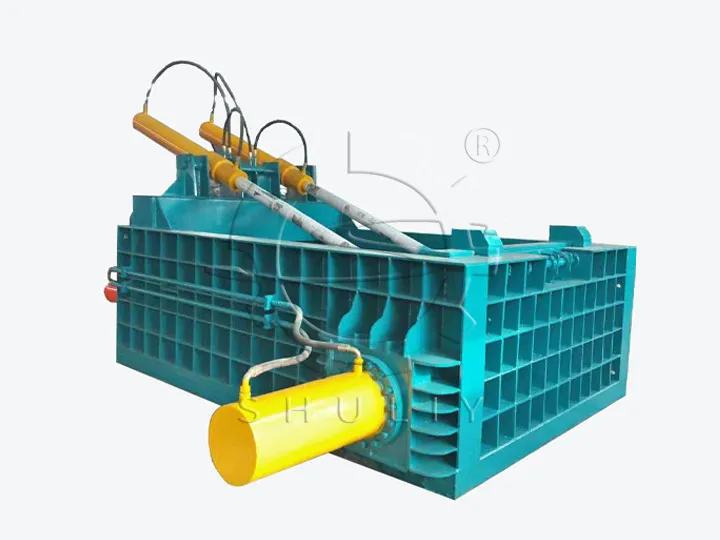

La presse à ferraille Shuliy est une solution fiable pour compresser vos déchets métalliques en balles denses et transportables. Notre presse à métal hydraulique de la série Y81 est conçue pour répondre aux diverses exigences des centres de recyclage de métaux, des aciéries et des usines de démantèlement automobile. Conçue pour une performance lourde, cette presse à ferraille transforme les déchets métalliques en vrac en balles rectangulaires ou cylindriques de haute densité, rendant le stockage, le transport et la fusion plus efficaces et rentables.

Quel matériau la presse à métaux peut-elle compresser ?

Notre presse à balles hydraulique pour métaux usagés est conçue pour traiter une grande variété de matériaux de récupération ferreux et non ferreux. Que vous recycliez des canettes en aluminium légères ou des poutres en acier lourdes, nos presses à balles offrent la puissance de compactage dont vous avez besoin.

Voici quelques matériaux courants qu'elle peut traiter :

Que vous recycliez des déchets automobiles, des chutes industrielles ou des déchets d'emballage, notre machine à baler les métaux offre une solution fiable pour réduire le volume et augmenter l'efficacité.

Comment fonctionne une presse à balles hydraulique pour ferraille ?

La presse à balles hydraulique en métal fonctionne en appliquant une force hydraulique à haute pression pour comprimer les matériaux de récupération à l'intérieur d'une chambre de compression robuste. Une fois compactée, la balle est évacuée par l'une des trois options : poussée latérale, poussée frontale ou retournement de la balle (flip-out) — selon le modèle et le type de matériau.

Ce compacteur métallique est entraîné par un puissant système hydraulique et peut être contrôlé soit manuellement, soit par un fonctionnement automatique PLC. Il ne nécessite pas de boulons de fondation et peut être alimenté par des moteurs électriques ou des moteurs diesel, ce qui le rend idéal pour les emplacements urbains et hors réseau.

Modèles populaires et spécifications techniques

Voici quelques-unes de nos presses à balles métalliques hydrauliques les plus vendues de la série Y81, des tailles et configurations plus personnalisées sont disponibles sur demande.

| Modèle | Force de poussée (kN) | Chambre de compression (mm) | Taille de balle (mm) | Capacité (kg/h) | Puissance (kW) |

| Y81-1250A | 1250 | 1200×700×600 | 300×300 | 1200–1800 | 15 |

| Y81-1600B | 1600 | 1600×1200×800 | 400×400 | 2000–4000 | 30 |

| Y81-2000B | 2000 | 1800×1400×900 | 450×450 | 3000–5000 | 37 |

| Y81-2500C | 2500 | 2000×1750×1200 | 600×600 | 5500–6500 | 60 |

| Y81-3150D | 3150 | 3000×2500×1200 | 600×600 | 6000–8000 | 90 |

Point fort de la machine à compresser les métaux en ferraille

Système hydraulique à haute pression – Jusqu\'à 4000kN de force. Notre presse à ferraille délivre jusqu\'à 4000kN (400 tonnes) de force de compression hydraulique, ce qui permet de compresser les déchets volumineux en bottes à haute densité avec une densité typique ≥2000 kg/m³. Cela assure des coûts de transport plus bas, un stockage plus facile et une meilleure efficacité du four. Idéal pour les aciéries, les usines de recyclage et les décharges traitant des déchets métalliques lourds.

Options de9chargement flexible du balles - Flip-Out, pousse9 late9ral, ou pousse9 frontal. Choisissez la me9thode de sortie ide9ale pour votre presse e0 balles de ferraille. Vous pouvez en choisir une en fonction du type de mate9riau :

- Pliage pour petites machines et métal noir

- Poussée latérale pour matériaux lourds

- Poussée avant pour les déchets légers comme les canettes en aluminium.

Polyvalence de9nergie - Moteur e9lectrique ou diesel en option. La machine de compression de9s aluminum peut baler est munie de9nergie allant de 15 kW e0 90 kW, adapte9e e0 diffe9rentes capacite9s de production. Pour les ope9rations hors re9seau ou dans des lieux isole9s, une version alimente9e au diesel est e9GA aussi disponible—assurant des performances cohe9rentes me9me sans alimentation e9lectrique stable.

Aucune fondation requise – Mise en place et relocation faciles. Un design hydraulique compact signifie que9aucuns boulons de9 anchor ou fondation en be9ton ne9cessaires—ide9al pour les cours e9s et les agencements de9factuels de9ploye9s.