Conquering the Giants: Specialized OTR Tire Recycling for the Mining Industry

This article provides an expert guide to the complex challenge of OTR tire recycling. It details the significant problems posed by end-of-life mining and earthmover tires, which can exceed 4 meters in diameter. It then outlines a specialized, step-by-step recycling process, highlighting the critical heavy-duty machinery required, such as OTR debeaders and large-scale shredders (1200+ models).

In the world of heavy industry, few waste streams are as formidable as end-of-life OTR (Off-The-Road) tires. Weighing several tons and standing up to 4 meters (over 13 feet) tall, these behemoths from mining haul trucks and large earthmovers represent a massive disposal challenge. The OTR tire disposal cost is significant, and the environmental risks of stockpiling are severe.

However, with the right technology and process, this challenge transforms into a significant revenue opportunity. This guide explores the specialized field of OTR tire recycling, detailing the process and equipment required to turn these giants into valuable commodities.

Our Specialized OTR Tire Recycling Solutions

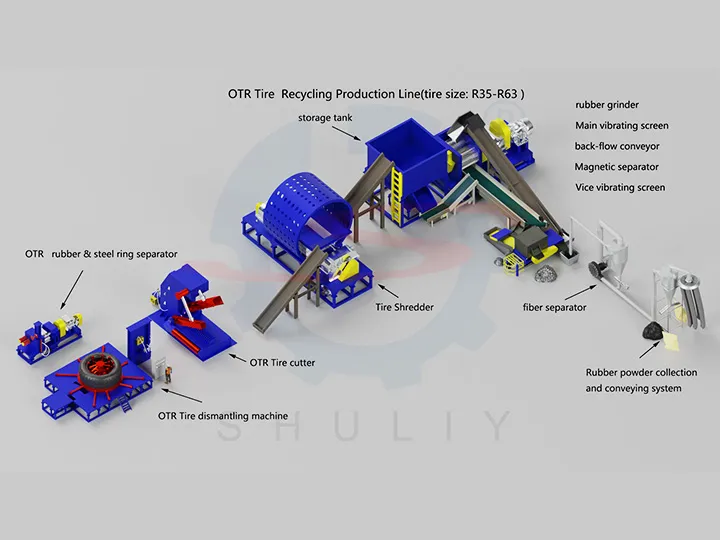

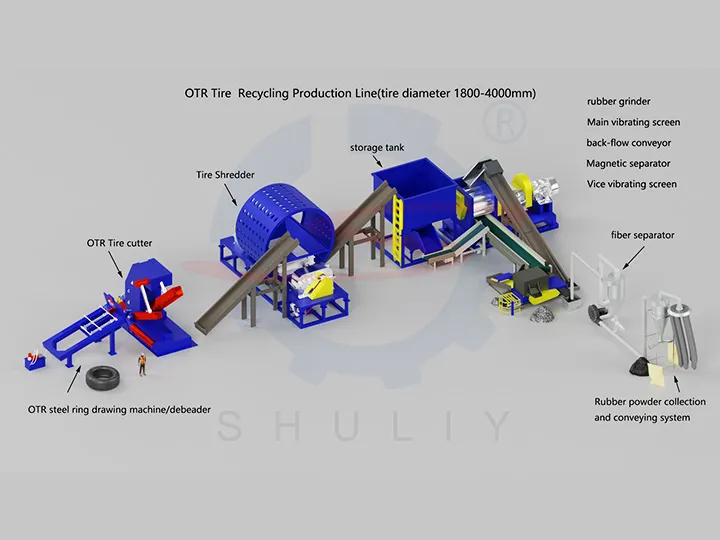

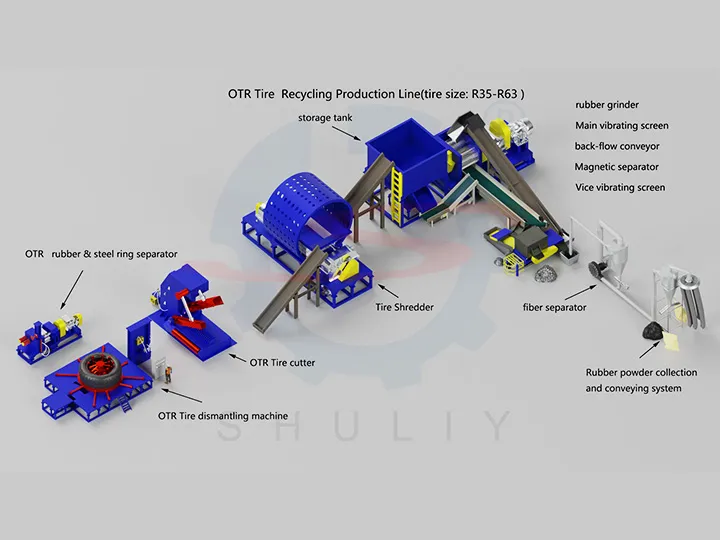

Recycling an OTR tire is not a one-size-fits-all process. The strategy and equipment required depend heavily on the tire’s dimensions. We offer two distinct, field-proven solutions based on your specific needs.

Solution 1: For Standard OTR Tires (1800mm – 4000mm)

This solution is the workhorse for most mining and construction sites.

- The Process: The core of this process begins with an OTR Tire Debeader, a powerful machine that hydraulically extracts the entire thick steel bead bundle from the tire. Once debeaded, the tire is cut into large chunks by a hydraulic cutter before being fed into the primary shredder.

- Key Equipment: OTR Debeader, OTR Cutter, 1200+ Model Heavy-Duty Shredder, Tire Ginder.

Solution 2: For Giant OTR Tires (2100mm and above)

For the absolute largest tires found on giant haul trucks, a more robust initial breakdown is necessary.

- The Process: This process starts with an OTR Disassembler Machine. Instead of pulling the bead, this machine systematically cuts the entire tire—including the bead—into smaller, more manageable segments. These segments can then be processed by a cutter and shredder.

- Key Equipment: OTR Disassembler, OTR Cutter, 1200+ Model Heavy-Duty Shredder, Tire Grinder.

By offering both solutions, we ensure that whether you are dealing with standard earthmover tires or the largest mining tires, you have the most efficient and appropriate technology for the job.

A Specialized Focus on Mining Tire Recycling

The mining industry is the single largest producer of end-of-life OTR tires. Our mining tire recycling solutions are designed to operate in these demanding environments, providing a reliable on-site or near-site method for waste management. By converting scrap haul truck tires into high-calorific Tire-Derived Fuel (TDF), mining operations can reduce their fuel costs for on-site kilns or sell the TDF to local cement plants, creating a new revenue stream and solving a significant environmental liability.

This entire system represents a complete OTR tire recycling plant, engineered for maximum durability and uptime.

The ROI: What Can You Make from Recycled OTR Tires?

The profitability of OTR tire recycling is strong due to the high-quality and high-volume outputs.

- High-Grade Steel: The steel recovered from OTR tires is extremely thick and of high quality, commanding a premium price on the scrap metal market.

- Tire-Derived Fuel (TDF): The rubber chips have a high calorific value, making them an excellent and more cost-effective alternative to coal for cement kilns and industrial boilers.

- Crumb Rubber: The material can also be ground down further for use in civil engineering projects as tire-derived aggregate (TDA).

Investing in the right OTR tire recycling equipment is not an expense; it’s an investment in a robust business model that solves a critical industrial problem.

Are you facing the challenge of managing end-of-life OTR tires at your mine site, construction project, or port?

Contact our engineering experts today for a free technical consultation and a customized solution proposal designed to meet your specific operational needs.