Sawdust Block Machine

Sawdust Brick Machine Introduction

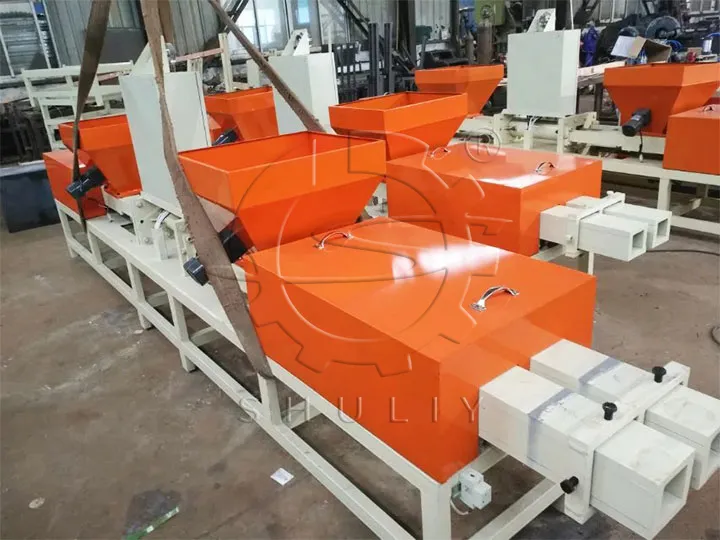

Shuliy pallet block making machine—also known as a sawdust pallet block machine or wood foot block press—is used to produce the supporting legs (blocks or feet) of wooden pallets. These machines compress mixed raw materials (wood waste + glue) under high temperature and pressure, forming uniform and durable blocks.

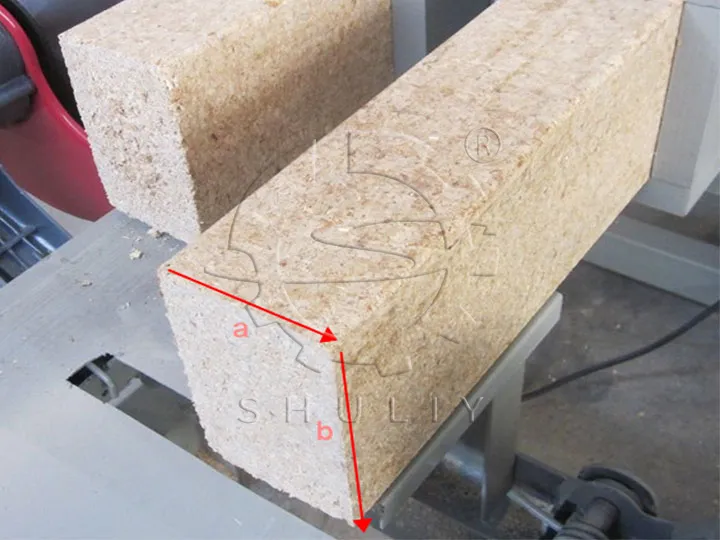

Our machine uses an electric heating system, hydraulic or screw feeding, and precision-cut molds to produce square or rectangular blocks of various sizes, such as 90×90 mm, 100×100 mm, or 145×145 mm. The blocks can be solid or with nail holes, suitable for automatic nailing lines.

Raw Materials & Glue for Compressed Wood Blocks Production

This wood pallet block machine is highly versatile and supports a wide range of raw materials:

The mixed material is combined with urea-formaldehyde glue (or other resins), usually at 16–20% concentration, to ensure strong bonding.

Final Products of Wood Pallet Block Making Machine

Technical Specifications

The technical specifications above refer to our best-selling pallet block machine model – SL-WB100. It offers a great balance between capacity, power efficiency, and output quality, making it ideal for most small to medium pallet production operations. However, we also offer a full range of models with higher output capacity, multiple block molds, or customized automation options to meet specific production goals.

Please fill out the contact form on our website if you have other confusing messages. Our sales team will help you select the right model and send detailed specifications and pricing.

| Parameter (Model SL-WB100) | Value |

| Motor Power | 15KW |

| Output Capacity | 4-5m3/24 hours |

| Mold Size | 90*90mm/ customizable |

| Block Density | 550-600 kg/m3 |

| Heating Method | Electric or thermal oil |

| Glue Usage | Urea-formaldehyde resin, ~16–20% |

| Control Systerm | PID temperature + pressure controller |

| Final Shape | Square block or strip, with/without nail holes |

For higher demands, we also offer multi-head pallet block machines and fully automated cutting systems.

Compressed Sawdust Blocks Application

Our compressed wood block machines are widely used by:

- Pallet manufacturers (domestic or export pallets)

- Furniture and wood factories recycling sawdust

- Packaging and logistics material producers

- Biomass processing and board factories

Our compressed wood log machines are especially popular in countries like India, Vietnam, Turkey, Nigeria, Saudi Arabia, and Russia, where wood waste recycling and export pallets are in high demand.