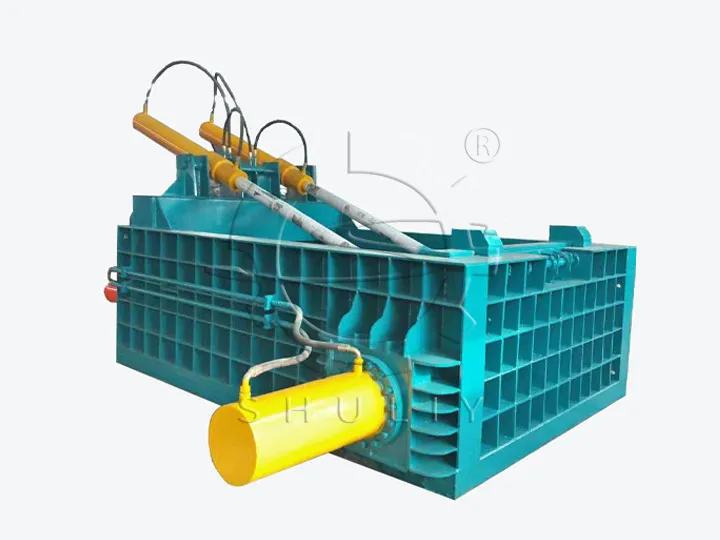

Scrap Metal Baler

Scrap Metal Baler Introduction

Shuliy Scrap metal baler is a reliable solution to compress your waste metal into dense, transportable bales. Our Y81 Series Hydraulic Metal Baler is engineered to meet the diverse demands of metal recycling yards, steel mills, and auto dismantling plants. Designed for heavy-duty performance, this scrap metal baler transforms loose metal waste into high-density rectangular or cylindrical bales—making storage, transport, and smelting more efficient and cost-effective.

What Material Can the Metal Baler Compress?

Our hydraulic scrap metal baler is designed to handle a wide variety of ferrous and non-ferrous scrap materials. Whether you are recycling lightweight aluminum cans or heavy steel beams, our balers deliver the compaction power you need.

Here are some common materials it can process:

Whether you’re recycling automotive scrap, industrial offcuts, or packaging waste, our metal baler machine provides a reliable solution to reduce volume and increase efficiency.

How Does A Hydraulic Scrap Baling Press Machine Work?

The hydraulic metal baling press machine operates by applying high-pressure hydraulic force to compress scrap materials inside a heavy-duty compression chamber. Once compacted, the bale is discharged via one of three options: side push, front push, or bale turning (flip-out)—depending on the model and material type.

This metal compactor is driven by a powerful hydraulic system and can be controlled either manually or via PLC automatic operation. It does not require foundation bolts and can be powered by electric motors or diesel engines, making it ideal for both urban and off-grid locations.

Popular Models and Technical Specifications

Here are some of our best-selling hydraulic metal balers from the Y81 Series, more customized sizes and configurations are available upon request.

| Model | Push Force (kN) | Compression Chamber (mm) | Bale Size (mm) | Capacity (kg/h) | Power(kW) |

| Y81-1250A | 1250 | 1200×700×600 | 300×300 | 1200–1800 | 15 |

| Y81-1600B | 1600 | 1600×1200×800 | 400×400 | 2000–4000 | 30 |

| Y81-2000B | 2000 | 1800×1400×900 | 450×450 | 3000–5000 | 37 |

| Y81-2500C | 2500 | 2000×1750×1200 | 600×600 | 5500–6500 | 60 |

| Y81-3150D | 3150 | 3000×2500×1200 | 600×600 | 6000–8000 | 90 |

Highlight of Scrap Metal Baling Machine

High-Pressure Hydraulic System – Up to 4000kN Force. Our scrap metal baler delivers up to 4000kN (400 tons) of hydraulic pressing force, enabling it to compress bulky scrap into high-density bales with a typical density of ≥2000 kg/m³. This ensures lower transportation costs, easier storage, and higher furnace efficiency. Ideal for steel mills, recycling plants, and scrapyards dealing with heavy-duty metal waste.

Flexible Bale Discharge Options – Flip-Out, Side Push, or Front Push. Choose the ideal output method for your scrap baling press machine. You can choose one based on material type:

- Flip-out for small machines and black metal

- Side push for heavy-duty materials

- Front push for lightweight scraps like aluminum cans

Power Versatility – Electric or Diesel Engine Optional. The aluminum can baler machine comes with motor power ranging from 15kW to 90kW, suitable for different production capacities. For off-grid operations or remote locations, a diesel-powered version is also available—ensuring consistent performance even without stable electricity supply.

No Foundation Required – Easy Setup & Relocation. Compact hydraulic design means no anchor bolts or concrete foundation needed—ideal for mobile scrap yards and flexible factory layouts.