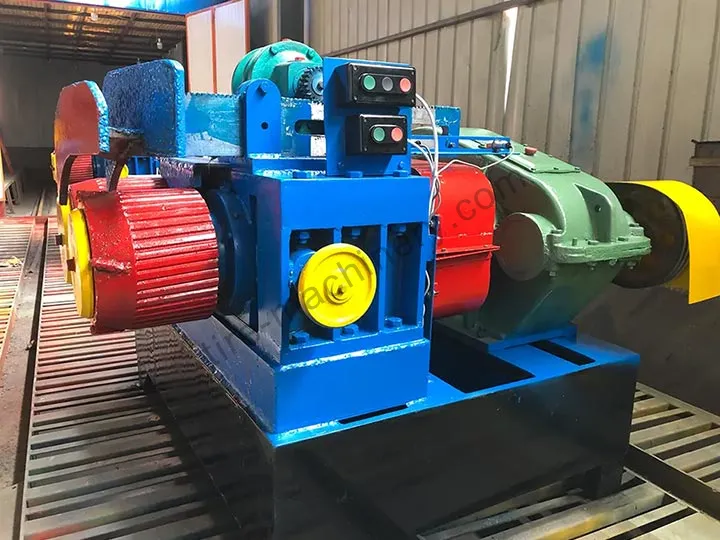

Tire Bead Wire Remover Machine

Main Applications

In waste tire recycling, removing the embedded steel wire from tire beads is the first and most critical step before shredding or granulating. Our tire wire drawing machine is purpose-built for this task. Also known as a tire bead wire remover machine or tire wire separator machine, it ensures that tire bead wires are safely, quickly, and completely separated.

Related

Tire Wire Drawing & Bead Removal

The tire wire drawing machine completes the separation by squeezing the tires by the two roller shafts rotating at the same speed relative to each other. When the tire bead enters the middle of the two roller shafts, the two roller shafts are driven by the gear motor to repeatedly squeeze the tire, the rubber is deformed by the squeezing, and finally separated from the wire completely.

The separated steel wire has high recycling value and is ideal for many metal products. The rest of the rubber ring can be combined with the strip cutter and block cutter for the next step of recycling.

Tire Bead Wire Extractor Technical Overview

The SWS-100 tire wire drawing machine features two counter-rotating rollers that pull the tire bead into the working zone. Once in position, the rollers exert extrusion, shearing, and tearing forces to gradually extract the steel bead wire embedded in the tire circle. This mechanical system works without excessive vibration or hydraulic systems, reducing maintenance needs.

The machine is powered by an 18.5 kW motor, offering strong torque and stable operation. With a processing capacity of up to 120 tire beads per hour, it meets the demands of medium to large-scale tire wire separator machine operations.

Its footprint is compact at 2.0m × 1.9m × 1.8m, and the structure weighs approximately 1800kg—a balanced size for durability and mobility. As a trusted tire bead wire extractor, this model combines simplicity, safety, and industrial-grade performance.

| Item | Technical Parameter |

| Motor Power | 18.5KW |

| Machine Capacity | 120pcs/h |

| Size (L*W*H) | 2m*1.9*1.8m |

| Weight | 1800kg |

More Machine Images

Final Output: Clean Rubber Rings and Recyclable Steel Wires

After processing with the tire wire drawing machine, the final output includes two valuable components: clean rubber rings with the bead wire fully removed, and extracted steel wires. These rubber rings are ideal for further crushing using a tire wire removing machine or granulator to produce rubber granules.

The extracted steel wires, separated efficiently by the tire wire separator, still hold significant recycling value and can be sold as scrap metal. This makes the tire wire drawing machine not only a critical pre-processing unit, but also a cost-saving solution that improves the quality of rubber output and supports material recovery.

extracted steel wires

extracted steel wires clean rubber rings with the bead wire fully removed

clean rubber rings with the bead wire fully removed steel wires extracted by tire bead wire extractor

steel wires extracted by tire bead wire extractor

Frequently Asked Questions

Most frequently asked questions by customers who purchased Shuliy tire wire drawing machine.This machine is designed to handle passenger car and light truck tire beads. The tire must be pre-cut into a ring (sidewall removed) before placing it into the tire bead wire remover machine.

Yes. The tire bead wire extractor is designed to completely pull out the steel ring from the tire bead. This prevents steel contamination in later shredding or granulating steps.

Not at all. Operators can learn to use this tire wire removing machine within one day. We provide video tutorials and operating manuals with every unit.

Hydraulic models are built for fully automatic lines or OTR tires. This tire wire drawing machine is a compact, mechanical tire bead wire remover machine designed for semi-automatic recycling lines, ideal for car and truck tires..

No. This model is designed for standard tires. For OTR bead removal, a larger hydraulic type debeader or OTR tire wire drawing machine may be required.

Definitely. It’s a compact, affordable tire bead wire remover machine that fits perfectly in semi-automatic or startup lines.

Only one person is required to run the tire wire removing machine, making it efficient and cost-saving.

Usually 7–15 working days after payment, depending on order volume..