Tire Recycling Machine Price: Semi vs. Full-Auto

This article provides a detailed comparison between semi-automatic and fully-automatic tire recycling lines to guide investment decisions. It breaks down the key differences across four critical areas: initial investment (machine price), long-term operational costs (labor, energy), production efficiency, and physical footprint. A clear decision-making guide helps users identify the best fit for their specific business scale and budget.

When planning to enter the tire recycling industry, one of the first and most significant decisions you’ll face is the choice between a semi-automatic and a fully-automatic production line. This decision goes far beyond the initial tire recycling machine price; it fundamentally shapes your operational efficiency, labor costs, and long-term return on investment (ROI).

This guide provides a clear, objective comparison to help you understand the trade-offs and determine which solution is the right fit for your business.

Defining the Difference: Manual vs. Automated Tire Recycling

Before we compare, let’s clarify what each term means.

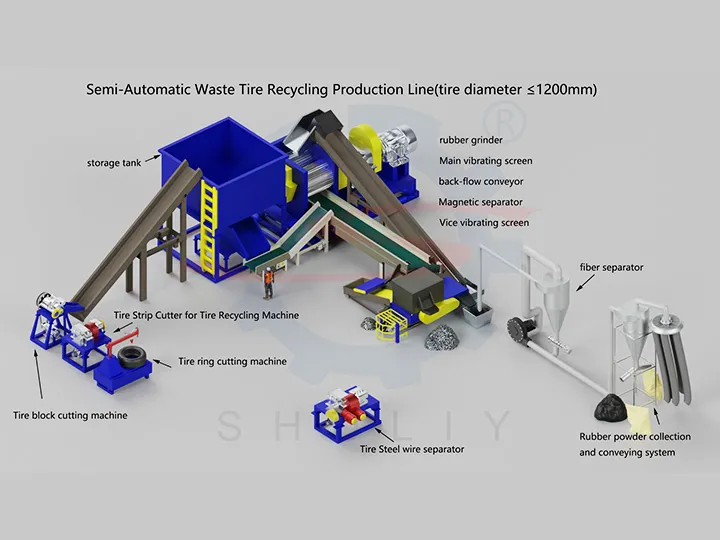

- A semi-automatic tire recycling line consists of standalone machines for each stage of the process (debeading, shredding, grinding). Material is typically moved between these stages manually, often using forklifts or manual labor.

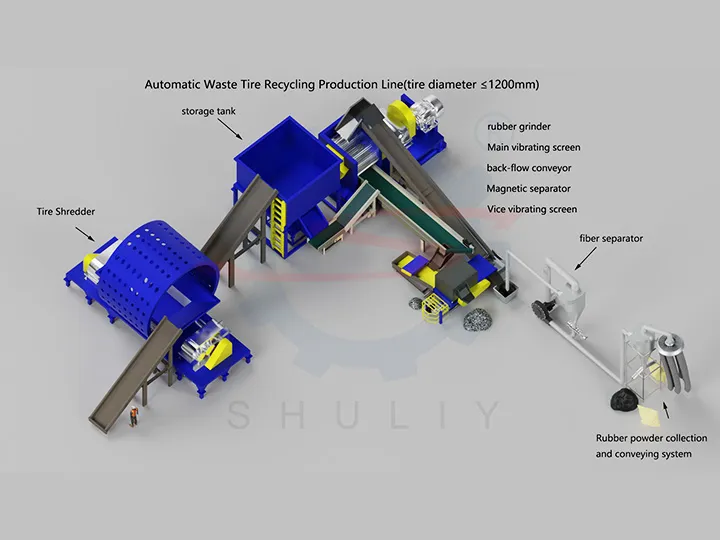

- A fully-automatic tire recycling plant integrates all machines into a single, continuous system. A network of conveyor belts and automated feeding systems handles material transfer, creating a seamless flow from whole tire to finished product with minimal human intervention.

Beyond the Initial Tire Recycling Machine Price: A Full Comparison

Let’s break down the semi-automatic vs full-automatic tire recycling debate across four critical areas.

| Factor | Semi-Automatic Line | Fully-Automatic Line |

|---|---|---|

| Initial Investment | Lower. The primary appeal is a more accessible entry-point tire recycling machine price. | Higher. Requires significant upfront capital for automation equipment like conveyors. |

| Operational Costs | Higher Long-Term. Heavily reliant on manual labor, leading to significant ongoing labor costs. | Lower Long-Term. Drastically reduces the need for operators, leading to substantial payroll savings. |

| Production Efficiency | Moderate. Output is limited by the speed of manual transfer between machines. | High. A continuous, uninterrupted workflow maximizes output capacity and efficiency. |

| Footprint & Flexibility | More Flexible. Machines can be arranged to fit unconventional spaces. Smaller initial footprint. | Larger & More Rigid. Requires a larger, well-planned layout to accommodate the integrated system. |

Choosing Your Line: Factoring in More Than the Tire Recycling Machine Price

There is no single “best” answer—only the most suitable solution for your specific circumstances.

Who Should Choose a Semi-Automatic Line?

A semi-automatic tire recycling line is often the ideal choice for:

- Startups and Small Businesses: The lower initial investment for tire recycling makes it a more feasible option for entrepreneurs with limited capital.

- Regions with Low Labor Costs: If affordable labor is readily available, the higher ongoing labor cost is less of a financial burden.

- Operations with a Focus on Flexibility: If you have a unique facility layout or plan to scale up in distinct phases, this option provides more adaptability.

This is a solid entry point for small scale tire recycling operations.

Who Should Choose a Fully-Automatic Line?

A fully-automatic tire recycling plant is the strategic choice for:

- Large-Scale Industrial Operations: For those targeting maximum production efficiency and volume, automation is essential.

- Regions with High Labor Costs: The significant reduction in manpower provides a clear and rapid tire recycling ROI.

- Businesses Prioritizing Consistency: Automation minimizes human error, ensuring a consistent and predictable output rate from your high capacity tire recycling plant.

This equipment selection decision is central to your business plan. It affects everything from your initial tire recycling machine price to your long-term profitability. By carefully weighing the upfront costs against the ongoing operational expenses and your production goals, you can confidently select the system that will serve as the foundation for your success.

Ultimately, the goal is to equip your facility with the right tools for the job. Whether that means starting with a flexible semi-automatic setup or investing in a powerhouse fully-automatic tire recycling plant, understanding the capabilities of each is key.

Contact our technical experts today for a free, customized cost-benefit analysis based on your specific business goals.