Деревообрабатывающая машина

Пилы для распила древесины — необходимые инструменты в современных лесохимических отраслях. Они обеспечивают эффективные, точные и универсальные решения для распила различных видов древесины. Независимо от того, работаете ли вы в небольшой мастерской или на крупном производственном предприятии, правильная пилорама может значительно повысить производительность. В этой статье мы введем два типа пилорам — вертикальные ленточные пилы и горизонтальные ленточные пилы — рассмотрим их преимущества, технические характеристики и идеальные применения.

Связанные

Выберите свою пилу для Timber

Вертикальная ленточная пила — Технические параметры

| Параметр | Описание |

|---|---|

| Мощность | 18.5 кВт / 37 кВт |

| Диаметр круга пилы | 900 мм / 1250 мм |

| Максимальный диаметр распила | 650 мм / 1500 мм |

| Ширина пильного полотна | 60 мм / 80 мм |

| Скорость пилы | 20–35 м/с |

| Метод подачи | Ручной / Пневматический / Гидравлический |

| Метод настройки | Электрический / управление CNC |

| Структура | Пильное полотно, пильный диск, основание, каркас и направляющая подачи древесины |

| Типы применимой древесины | Твердая древесина (дуб, береза, розовый дерево), мягкая древесина (сосна), квадратная заготовка, панели, фанера и композитные плиты |

Дополнительное описание:

Вертикальная пила-модуль для древесины — очень эффективная система резки, подходящая для небольших и средних предприятий по переработке древесины. Диапазон мощности от 18,5 кВт до 37 кВт обеспечивает стабильную и мощную резку. Диаметр пильного колеса от 900 мм до 1250 мм улучшает точность реза и баланс при эксплуатации на различных диапазонах заготовки.

Ее максимальный диаметр распила достигает 1500 мм, что позволяет обрабатывать как средние, так и относительно крупные стоки. Ширина пилы (60–80 мм) и скорость резания (20–35 м/с) обеспечивают плавную, точную и эффективную работу при сохранении отличной поверхности древесины.

Система подачи поддерживает ручной, пневматический и гидравлический режимы, обеспечивая гибкость в различных производственных сценариях. С электрической или ЧПУ коррекцией операторы могут точно настроить скорость и положение подачи для максимальной точности.

Это делает вертикальную пилу идеальной для массового производства древесины — особенно для деревообрабатывающих предприятий, которым необходимы и скорость, и экономичность.

Больше изображений вертикальной пилы для продажи

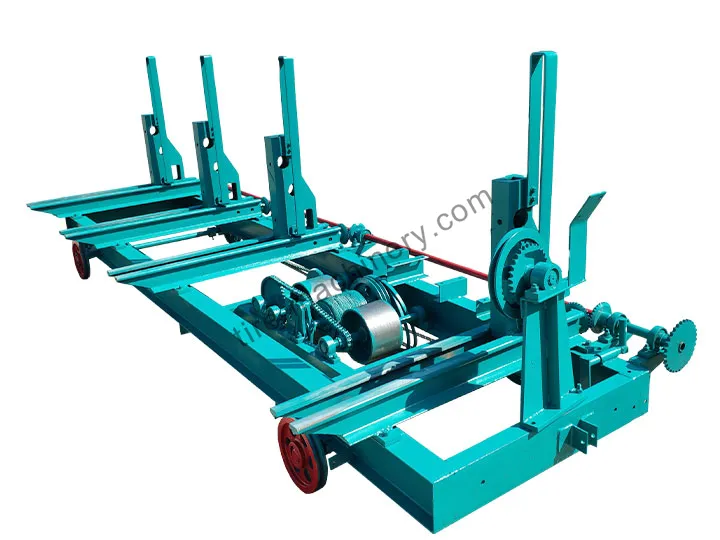

Параметры горизонтальной ленточной пилы — технические

| Параметр | Описание |

|---|---|

| Мощность | 15 кВт / 55 кВт |

| Диаметр круга пилы | 700 мм / 1250 мм |

| Максимальный диаметр распила | 700 мм / 2500 мм |

| Ширина пильного полотна | 80 мм / 100 мм |

| Скорость пилы | 15–30 м/с |

| Система натяжения | Гидравлическая система натяжения |

| Система подъёма | Редуктор червячной передачи в сочетании с цепной передачей |

| Тип питания | Электрический двигатель / Дизельный двигатель / Бензиновый двигатель |

| Гусеничная конструкция | Усиленная квадратная стальная труба — высокая жесткость и сопротивление деформации |

| Максимальная длина распила | 6 м – 15 м |

| Максимальная высота распила | 650 мм – 1200 мм |

| Метод установки | Не требуется фундамент; может работать на ровной поверхности |

| Опция мобильности | Можно оснащать колесами для полевых или лесных работ |

| Типы применимой древесины | Бревна, твердые породы, хвойные породы, фанера, композитная древесина и veneers |

Дополнительное описание:

Горизонтальная ленточная пила — это прочная система резки, созданная для распила крупномерных бревен и промышленной обработки древесины. Основная мощность двигателя составляет от 15 кВт до 55 кВт, что обеспечивает сильную режущую силу и стабильную работу даже при больших нагрузках. Диаметр пильного колеса от 700 мм до 1250 мм поддерживает баланс реза и повышает точность во время длительной эксплуатации.

Поддерживает максимальный диаметр распила 2500 мм и длины распила до 15 метров, что позволяет без труда обрабатывать крупномерные бревна. Гидравлическая система натяжения облегчает замену и настройку пилы, значительно сокращая время простоя в производстве.

Подъёмная система сочетает редуктор червячной передачи с цепной передачей, обеспечивая плавное и точное вертикальное движение рамы пилы. Укрепленная квадратная дорожка обеспечивает исключительную жесткость, сопротивляясь деформации под тяжелыми нагрузками, тем самым обеспечивая долгий срок службы.

Мachine может питаться электродвигателями, дизельными или бензиновыми двигателями, что позволяет операторам адаптироваться к различным условиям работы, включая удалённые лесохозяйственные участки. Кроме того, установка без фундамента и возможность дизайна с колесами делают его идеальным для мобильной распиловки в лесных операциях, обеспечивая исключительную гибкость для работы на улице.