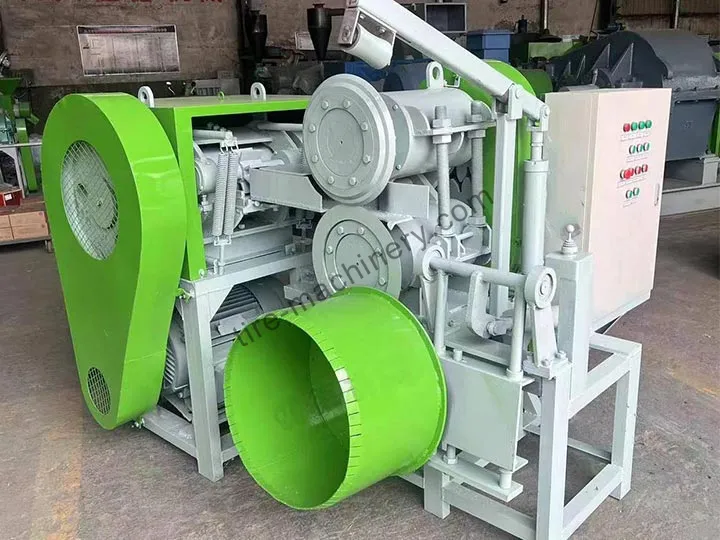

TR-1200 Pro: Industrial-Grade Automatic Rubber Block Cutter

Driven by a high-torque 40.5kW system, the TR-1200 Pro automates the transition from whole tires to high-value, uniform 50-80mm TDF chips. With a throughput of 20-30 tires per hour, it maximizes industrial efficiency and slashes labor costs, providing a reliable foundation for any large-scale recycling plant.

Related

Automatic Rubber Block Cutter Instruction

The TR-1200 Pro automatic rubber block cutter is designed to bridge the gap between whole tire collection and downstream granulation or pyrolysis. Unlike manual slicing methods, this system automates the destruction of the tire structure, converting whole tires into manageable rubber blocks in a single, continuous operation. This level of automation significantly reduces labor intensity and increases the safety of the workspace.

Technical Parameters of TR-1200 Pro Cutter

The following data defines the operational limits and performance capabilities of the TR-1200 Pro. These specifications are optimized for industrial throughput and reliability.

| Parameter | Specification |

|---|---|

| Model Name | TR-1200 Pro |

| Primary Function | Whole tire to 50-80mm block cutting |

| Motor Power | 40.5 kW |

| Voltage/Frequency | 380V / 50Hz |

| Maximum Tire Diameter | < 1200 mm |

| Processing Capacity | 20 – 30 tires / hour |

| Output Size | 50 – 80 mm |

| Machine Weight | 1800 kg |

| Dimensions | 2000 * 1800 * 1580 mm |

More Machine Images

High-Power Performance for Industrial Recycling

The core of the automatic rubber block cutter is its 40.5kW high-torque motor system. This power rating is essential for overcoming the structural integrity of steel-belted tires without causing mechanical fatigue. By maintaining a processing speed of 20 to 30 tires per hour, the TR-1200 Pro ensures a steady flow of material, preventing bottlenecks in the tire recycling line. The 1800kg frame is constructed from reinforced steel to absorb the significant kinetic energy generated during the cutting process, ensuring long-term structural stability.

Precision Engineering as a Tire Cuber Machine

As a specialized tire cuber machine, the TR-1200 Pro focuses on output consistency. Producing uniform 50-80mm blocks is vital for facilities that supply material for Tire Derived Fuel (TDF) or secondary shredding. Consistent block size allows for even heat distribution in pyrolysis reactors and prevents irregular loading in secondary granulators. The internal blade configuration is designed to shear through both the tread and sidewall simultaneously, maintaining the 50-80mm specification across varying tire widths.

Versatile Scrap Tire Cutting Performance

Whether utilized as a scrap tire cutting machine or a scrap tyre cutting machine for international markets, the TR-1200 Pro handles a wide variety of waste tires under 1200mm in diameter. This includes standard passenger car tires, SUVs, and light truck tires. The automated feeding and cutting cycle ensure that the operator remains at a safe distance from the cutting zone, a critical improvement over traditional manual cutters.

Applications: A Tire Recycling Machine for Chunks

The TR-1200 Pro is more than just a cutter; it is a high-efficiency tire recycling machine for chunks that serves multiple industries. The 50-80mm output is the ideal feedstock for several recycling pathways:

- Pyrolysis Plants: Provides the optimal surface-area-to-volume ratio for thermal decomposition.

- TDF Production: Meets the sizing requirements for industrial kilns and boilers.

- Secondary Crushing: Acts as the perfect pre-shredding stage to extend the life of fine-grinding rollers.

By integrating the automatic rubber block cutter into your facility, you ensure a professional, automated approach to tire waste management that prioritizes throughput and operational longevity.

For detailed pricing and shipping configurations for the TR-1200 Pro tire cutter, contact our technical sales team to discuss your specific tyre recycling plant requirements.