Rubber Tile Making Machine

The rubber tile making machine can produces premium, high-density flooring using 120 tons of pressure. Its automated system and exclusive Teflon moulds boost your factory’s efficiency, cut operational costs, and deliver a faster return on investment.

Related

Rubber Tile Making Machine Instruction

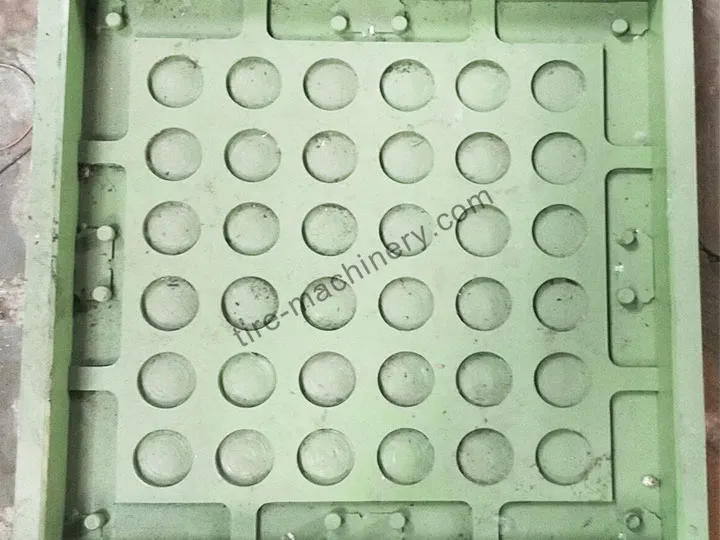

The SL-1200 is an industrial-grade rubber tile making machine engineered for high-volume, continuous production. At its core, a robust 4-cylinder hydraulic system delivers a nominal clamping force of 1.2 MN (120 Tons), ensuring exceptional density and durability in every tile. The machine operates with two independent working layers, each equipped with a 1100x1100mm heating plate that maintains a precise thermal profile up to 200°C.

Managed by an intuitive PLC control system, it executes rapid vulcanization cycles of just 3-8 minutes. This combination of raw power and intelligent automation makes it the ideal cornerstone for any serious Gym Flooring Production Line or Rubber Paver Production Line, converting raw granules from a tire recycling line into high-margin architectural products.

Raw Material Requirements: The Link to a Complete Recycling Solution

The primary raw material for the RT-Vulcan 1200 is recycled rubber granules, a high-value commodity derived directly from end-of-life tires. For optimal results, a dual-layer production method is recommended:

- Base Layer: Utilizes 1-4mm coarse rubber granules. This material provides structural integrity and excellent shock absorption. It is the main output from a standard tire recycling line.

- Top Layer: Employs 0.6-1mm fine rubber powder, often mixed with pigments to create vibrant, wear-resistant surfaces. This finer material is produced by the rubber mill unit within our advanced recycling systems.

By integrating the SL-1200 with our comprehensive tire recycling line, you create a vertically integrated “waste-to-product” factory. This synergy not only guarantees a stable, low-cost supply of high-quality granules but also maximizes your profitability by capturing the full value of every recycled tire.

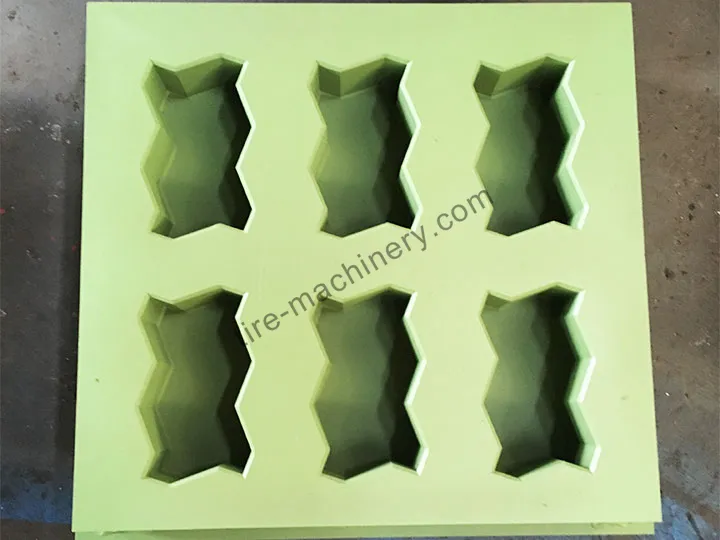

High-Precision Moulds for Versatile & Flawless Finished Products

The SL-1200 achieves its production versatility through high-precision, Teflon-plated moulds designed for extreme durability and operational ease. The innovative Teflon coating creates a permanent non-stick surface, effectively removing the need for recurring release agent applications and significantly accelerating the de-moulding process.

Each mould set is engineered with integrated adjusting tooling, allowing operators to produce finished products in four distinct thicknesses—15, 20, 25, and 30mm—within a single mould frame. Whether producing standard 500x500mm and 1000x1000mm square tiles or specialized roadside stones (1000x80x210mm) and interlocking pavers, the resulting products exhibit superior density, uniform edges, and a blemish-free finish. These high-quality outputs are ideal for professional gym flooring, high-traffic public playgrounds, and heavy-duty industrial paving.

Key Features of Rubber Tile Forming Machine

Recycled Rubber Tile Forming Machine Specification

Reliability in a Rubber Mat Compressionolding Machine depends on thermal stability. The SL-1200 uses high-efficiency electric heating tubes to reach a maximum temperature of 200°C. The 60mm thick hot plates act as heat sinks, maintaining a stable temperature profile even during continuous material feeding.

| Component | Technical Data |

|---|---|

| Nominal Clamping Force | 1.2 MN (120 Tons) |

| Plate Dimensions | 1100 x 1100 x 60 mm |

| **Cinder Diameter/Qty** | Φ160 mm / 4 units |

| Motor Power | 3.0 kW |

| **x Working Pressure** | 20 Mpa |

| Production Speed | 3-8 minutes per cycle |

| Equipment Dimensions | 3400 x 1400 x 1800 mm |