Rubber Tire Shredder Machine

Main Applications

The industrial tire shredder is widely used in the waste tire recycling industry, which can efficiently process various types of tires, including small car tires, truck tires and disintegrated construction machinery tires (OTR). The size of the shredded rubber block is 50-100mm, which can be used for subsequent processes such as crushing and powdering, rubber refining, pyrolysis fuel, etc. It is an indispensable key equipment in the tire recycling system.

Related

Car Truck Tire Shredder Introduction

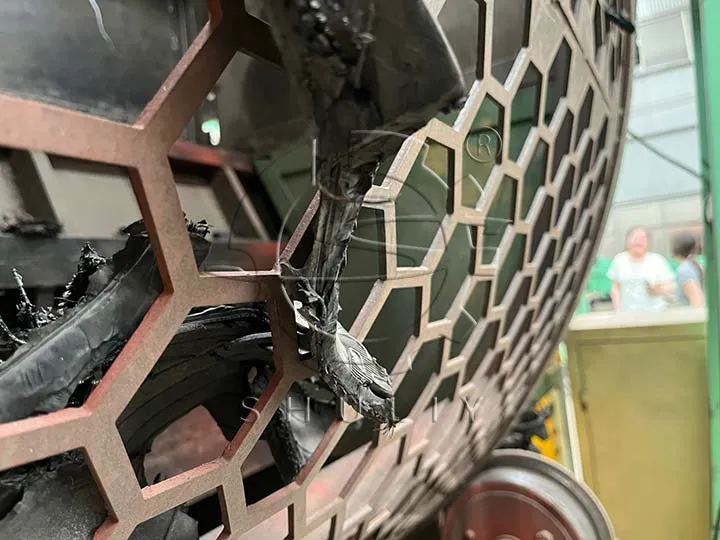

The rubber tire shredder adopts double shaft low speed and high torque design, through two reverse rotating knife shafts with high strength alloy blades, it can tear, squeeze and shear the waste tires. Waste tires are fed into the shredding chamber by the conveyor belt, and the equipment shreds the tires into small pieces of rubber according to the set discharge size.

Qualified rubber pieces are automatically discharged through the screen mesh, and those not up to standard will return to be shredded again until the size is qualified. With stable operation, low noise and low energy consumption, the tire shredder is especially suitable for continuous industrialized operation.

Equipment Highlights

Various models available: Shuliy truck tire shredder for sale has different models include 900, 1000, 1200, 1500, 1800 models, with processing capacity ranging from 2t/h to 20t/h, meeting the application scenarios from small and medium-sized to large-scale tire recycling plants.

Powerful power system: The industrial shredder machine motor power ranges from 64.5kW to 328.5kW, equipped with high-efficiency reducer and powerful gear transmission system to ensure stable operation under high load.

Uniform and Controlled Discharge Size: Discharge size ranges from 50mm to 100mm, which is suitable for subsequent crushing, refining or pyrolysis processes. Adopting screen to control the size, unqualified particles are automatically returned to be shredded again.

shredded rubber blocks

shredded rubber blocks pulverized rubber blocks

pulverized rubber blocks

High-strength blades: The blades are made of composite alloy material, the thickness of the blades ranges from 50mm to 100mm, and the diameter of the blades can be up to 650mm, which has good abrasion resistance and impact resistance, and prolongs the service life.

tyre shredder blades

tyre shredder blades tyre shredder screen

tyre shredder screen

Sturdy structure, flexible footprint: Shuliy car tire shredder is of all-steel welded structure, with good mechanical strength and operational stability, flexible footprint size, suitable for a variety of site layout requirements.

Intelligent Conveyor System: our rubber shredder for sale is equipped with conveyor belt system with width from 950mm to 1550mm, high degree of automation reduces labor input and improves overall operational efficiency.

Tire Shredder for Sale Technical Specification

Our Tire Shredder Machine is designed to cut car tires, truck tires, and dismantled OTR tires into 50–100mm rubber chips. We offer five standard models to suit different processing needs, from small recycling workshops to large-scale industrial plants.

The entry-level 900 model features a 64.5kW motor, capable of processing 2 tons per hour, and is suitable for general passenger tires under 900mm in diameter.

The 1000 and 1200 models offer 4–6 tons/hour capacity, with blade diameters of up to 510mm, ideal for mid-sized operations processing tires up to 1200mm. These are excellent options for buyers looking for a reliable tyre shredder for sale with stable output.

For large-scale projects, the 1500 and 1800 models are true industrial tire shredders, with motor power up to 328.5kW and throughput reaching 15–20 tons per hour. These models are specifically designed as heavy-duty tyre shredders for trucks and buses, including engineering tires up to 1400mm in diameter.

| Model | Power(kW) | Output (ton/h) | Input size (mm) | Output size (mm) | Machine size (m) | Weight (ton) |

| SL-900 | 64.5 | 2 | <900 | 50 | 4*2.2*2.8 | 10 |

| SL-1000 | 94.5 | 4 | <1000 | 60 | 5*2.6*3.2 | 13 |

| SL-1200 | 157 | 5-6 | <1200 | 60 | 5*2.6*3.2 | 15.8 |

| SL-1500 | 188.5 | 8-10 | <1200 | 75 | 20*10*3.5 | 18.6 |

| SL-1800 | 328.5 | 15-20 | <1400 | 100 | 20*12*4 | 26 |

For complete technical information, blade details, tire shredder price, video demonstration or customized project solutions, please feel free to contact us, Shuliy as a professional tire shredder manufacturer will provide you with the most suitable tire shredding solutions for your needs.

More Rubber Tire Shredder Images

Our machines aren’t just functional — they’re also designed to reflect your brand identity. In the additional images below, you’ll see examples of equipment delivered in custom colors, from bold industrial yellow to sleek dark gray. We support color customization to match your company’s branding, facility theme, or product line aesthetics.

Beyond color, we offer flexible customization options including:

- Voltage and plug types for different countries (e.g., 415V 50Hz, 3-phase)

- Logo engraving or sticker placement of your tire recycling company or plant

- Conveyor length of your industrial shredder machine and layout adjustments for your entire recycling plant

More Than Just Tire Shredding

While this shredder is primarily designed for waste tires, it’s also widely used in many other recycling sectors. With its heavy-duty blades and customizable configuration, the machine is capable of shredding a wide range of materials, including: plastic barrels and containers, PE pipes, wooden pallets, mattresses, sofas, scrap metals like aluminum casings and engine shells, municipal waste, RDF derivatives, fabric waste, and more.

Learn more about shredding different materials in our blog post, including setup suggestions and best practices for plastic, wood, metal, textiles, and RDF waste.

Frequently Asked Questions

Most frequently asked questions by customers who purchased Shuliy tyre shredder for sale.Our tire shredder machine supports tire diameters from 900mm to 1400mm, depending on the model. It can process car tires, truck tires, and dismantled OTR tires.

The output size is adjustable between 50–100mm, making it ideal for downstream granulation or TDF use. Each industrial tire shredder is equipped with blades that can be customized for your desired output.

The blades are made of high-strength alloy composite, designed for long wear resistance. Depending on tire type and usage, blades typically last 6–12 months and can be re-sharpened..

Yes. We stock spare parts including cutters, motors, and gearboxes. For each tyre shredder for sale, we offer a recommended spare parts package.

No special foundation is needed. The heavy-duty tyre shredder is delivered as a complete unit. Basic leveling and 3-phase industrial power (380V/415V/440V) are sufficient.

Our largest models offer 15–20 tons per hour, which means over 100 tons per day in a multi-shift operation. The shredder is scalable for high-volume tire recycling plants.

Yes. We provide voltage customization (380V, 415V, 440V) and support CE-compliance. Whether you’re in the Middle East, South Africa, Asia, or South America, we adapt to your local standards.

We offer full support: industrial shredder manuals, remote video setup, spare parts packages, and blade sharpening guides. Our industrial tire shredder clients also enjoy long-term technical service and layout consultation.