Ligne de production de poudre de caoutchouc

Chaque ligne de production de poudre de caoutchouc prend en charge des configurations personnalisées, en tenant compte de l'efficacité, du coût et des normes environnementales, répondant aux besoins de tous les scénarios, du recyclage des pneus à petite et moyenne échelle à l'échelle industrielle. Shuliy propose des solutions de recyclage comprenant le type semi-automatique, la ligne entièrement automatique-1, la ligne entièrement automatique-2, la ligne de recyclage standard pour pneus OTR, la ligne de recyclage pour pneus OTR géants.

Multi-spécification

Couvrant des pneus avec des diamètres allant de 300 à 4000 mm, une ligne peut répondre à diverses demandes.

Prétraitement haute efficacité

Processus modulaire (découpe de bagues / dessin, découpe de bandes / coupe, déchiquetage, séparation de fils d'acier / nylon, broyage).

Poudre de caoutchouc de haute qualité

maillage 10-80 ajustable, pureté ≥99,2%, pour répondre aux matériaux de revêtement de piste, modification de l'asphalte, caoutchouc recyclé, etc.

Personnalisé ligne de production de poudre de caoutchouc pour le recyclage des pneus

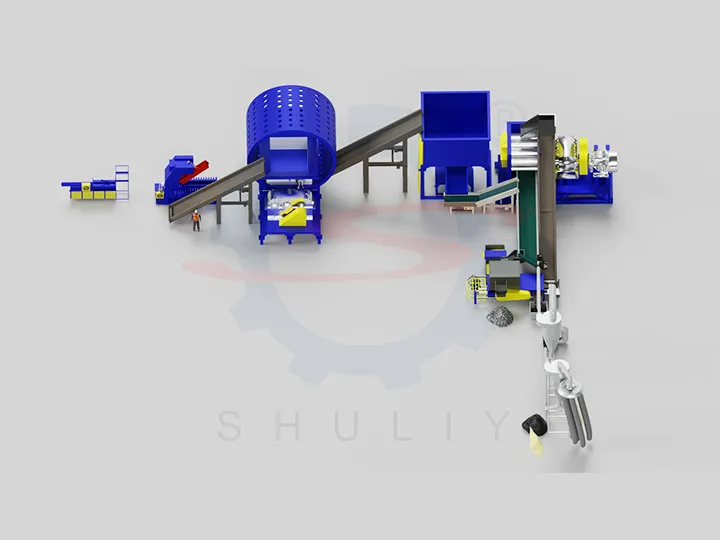

Ligne de production de poudre de caoutchouc semi-automatique

Seuil d'investissement faible : convient aux opérations à petite échelle, particulièrement adapté aux recycleurs ayant des contraintes budgétaires ou aux nouveaux recycleurs pour construire rapidement une usine.

Mise à niveau progressive et expansion fluide : Initialement, seuls les modules de coupe, de déchiquetage et de déchiquetage centraux peuvent être configurés, puis ajouter le criblage et d'autres équipements, pour obtenir une double amélioration de la capacité de production et de la qualité.

Paramètres clés

Capacité quotidienne 533_d63890-37> | 1-3 tonnes par jour 533_272b19-41> |

Efficacité de séparation acier-nylon 533_899c0f-d1> | 99.2% 533_50167b-05> |

Taille de la poudre de gomme 533_c7f19c-ff> | 10-40 mailles (2,5-0,63 mm) 533_8f3ee2-36> |

Puissance du moteur 533_03b0f2-79> | 30–150 kW (selon le modèle) 533_2960ef-81> |

Avantages

Ligne de production de poudre de caoutchouc entièrement automatique

Automatisation complète du processus : Prétraitement – coupe – concassage grossier – concassage fin conception intégrée, transport fluide des matériaux, réduisant la stagnation intermédiaire.

Concassage à double étage, sortie à haut rendement : En combinant les deux processus de concassage, concasseur grossier et concasseur fin, il permet un concassage rapide et un broyage en profondeur.

Fonctionnement continu : faible maintenance : le système de stockage et de déchargement automatique assure un approvisionnement continu en matériaux.

Paramètres clés

Capacité quotidienne 533_4984b0-f4> | 3-35 tonnes par jour (24 heures) 533_9506e5-9a> |

Consommation d'énergie 533_c1b5de-c5> | ≤ 40 kWh/ton 533_6d7063-44> |

Taille de la poudre 533_35914b-d0> | 10-80 mailles 533_c99b9e-11> |

Pureté de la poudre 533_f426d0-82> | 99.2% 533_e26b69-a7> |

Avantages

Ligne de production de poudre de caoutchouc entièrement automatiqueⅡ

Exigence de taille : Notre ligne de production de poudre de caoutchouc entièrement automatisée est conçue pour le recyclage efficace des pneus usagés jusqu'à 1200 mm de diamètre.

Processus de prétraitement simplifié : L'utilisation d'une coupe-pneu multifonction intègre le processus de prétraitement fastidieux (coupe de flancs et coupe de blocs en une seule machine), améliore l'efficacité du prétraitement des pneus et économise l'espace de l'usine.

Paramètres clés

Capacité quotidienne 533_21994d-2e> | 3-35 tonnes par jour (24 heures) 533_9b35f1-1f> |

Puissance totale 533_58c56f-ef> | 180-220 kW (selon la configuration) 533_a84e33-a1> |

Taille de la poudre 533_c24b8f-03> | Tamis 10-40 (Écrans personnalisables) 533_433fc3-1a> |

Taux de séparation des fils d'acier 533_7846ea-4b> | 99,2 % ou plus 533_7be1b6-2b> |

Avantages

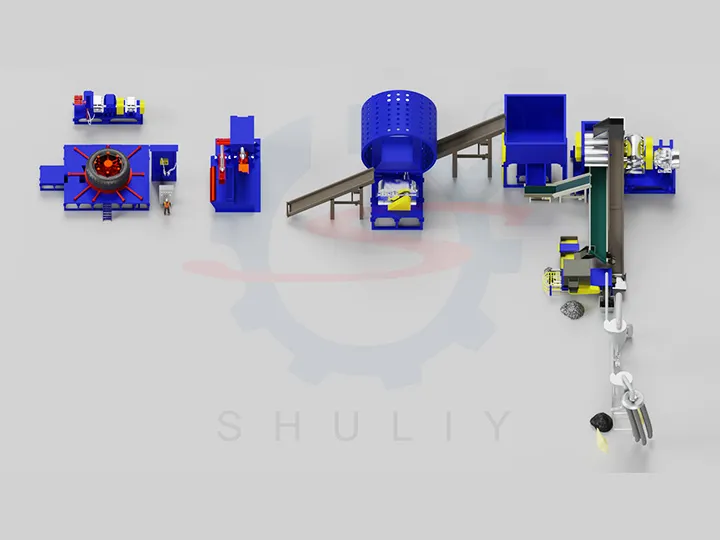

Usine de recyclage de pneus OTR standard

Recyclage de pneus de grande taille : Cette ligne de recyclage est conçue pour traiter les pneus d'ingénierie et miniers surdimensionnés, d'un diamètre compris entre 1400 mm et 4000 mm, pour les industries minière, de la construction et portuaire.

Options personnalisées : Des solutions personnalisées sont fournies pour des pneus de différentes tailles et configurations afin d'assurer un broyage efficace et une production de poudre de caoutchouc de haute pureté.

Paramètres clés

Capacité quotidienne 533_5470e8-68> | 10-35 tonnes par jour (24 heures) 533_3765fd-bc> |

Application 533_744ab8-af> | grandes pneus d'ingénierie, de minage et de camions lourds 533_1cf467-fa> |

Diamètre de pneu 533_3a7bdb-40> | 1400-4000 mm 533_3ce75e-eb> |

Taille finale de la poudre 533_d30e69-f8> | 10-80 mailles 533_fed925-98> |

Aperçu de l'équipement

Processus principal

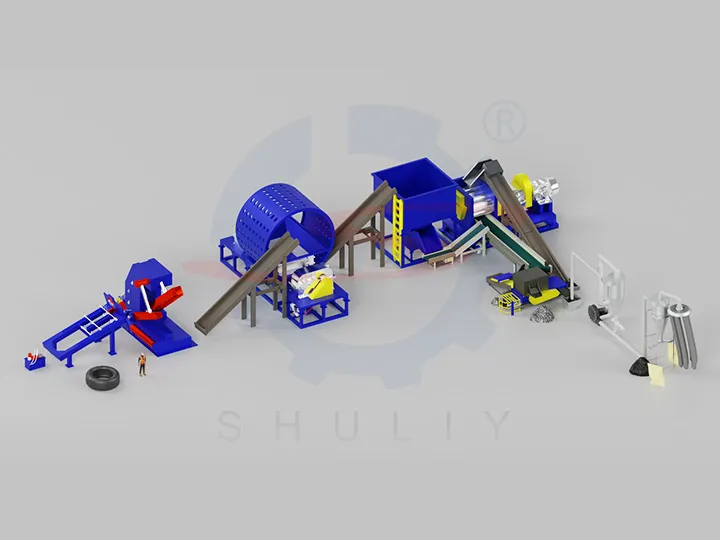

Ligne de traitement de pneus OTR géante

Pour la demande de recyclage et de traitement des grands pneus de construction d'un diamètre de 2100 mm et plus, nous fournissons :

La ligne de traitement des pneus comprend un désintégrateur OTR, un coupeur, un séparateur de jante, un déchiqueteur de grande taille, un système de stockage automatique, une machine à poudre de caoutchouc de grande taille (XKP450 et plus), un séparateur d'air en nylon et un système de collecte et de transport de poudre de caoutchouc.

Cette solution peut réaliser l'ensemble du processus de traitement, depuis le démontage initial, la découpe et la séparation des pneus surdimensionnés, jusqu'à la déchiquetage du caoutchouc, le broyage fin et la séparation du nylon.

Paramètres clés

Capacité quotidienne 533_4d4f6a-de> | 5-20 tonnes par jour 533_be9619-3e> |

Application 533_cded56-d6> | grandes pneus d'ingénierie, de minage et de camions lourds 533_bd63fa-3e> |

Diamètre du pneu 533_6db4cf-a1> | plus de 2100 mm 533_b04685-92> |

Taille de la poudre de caoutchouc 533_5a878f-3d> | 10-80 mailles 533_fef2eb-6a> |

Aperçu de l'équipement

Processus principal

Types de pneus en fin de vie

Notre usine de déchiqueteuse de pneus est capable de traiter une large gamme de pneus usagés, allant des véhicules de tourisme quotidiens aux équipements industriels et agricoles. Voici les principales catégories :

Applications polyvalentes des sous-produits du recyclage des pneus.

Fil d'acier recyclé

Application de fibre de nylon fine

Vous voulez un projet OTR ?

Shuliy a développé un système de traitement entièrement automatisé pour les pneus OTR surdimensionnés (diamètre de 1400 à 4000 mm, modèles spéciaux de 2100 mm + disponibles) pour les machines de construction et d'exploitation minière, intégrant le déchiquetage hydraulique, la séparation intelligente des fils et le transport automatisé.

OTR Solutions

Votre système complet pour le démantèlement de pneus OTR et la récupération du caoutchouc.

Ligne de recyclage de pneus OTR standard

Le diamètre de traitement maximum est de 4000 mm

Processus : dessin → découpe → déchiquetage → pulvérisation → séparation → collecte

Ligne de recyclage de pneus OTR géants

Le diamètre de traitement minimum est de 2100 mm

Processus : désintégration de pneus entiers → découpe → séparation des fils → déchiquetage → écrasement → séparation → collecte

Machine de démantèlement

Le désintégrateur OTR peut couper et séparer les pneus de construction de plus de 2100 mm de diamètre (R35-R63) en 4 à 6 parties telles que l'ouverture de talon, la bande de roulement et le sommet du pneu.

Extracteur de fil à perles

Séparateur de jante pour séparer les fils d'acier de jante de pneus de construction de 1400 à 4000 mm

Débeurreur d'acier de pneu

La machine à débeader par tirage de fil OTR extrait directement les fils d'acier de jante de pneus de construction de 1800 à 4000 mm.

Questions Fréquemment Posées

Nous avons listé plusieurs questions qui intéressent la plupart des recycleurs. Jetez un œil !