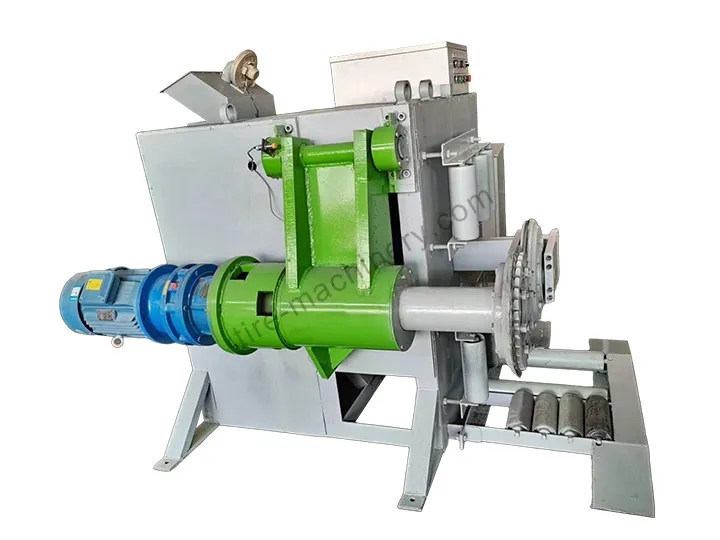

SL-1400 Tire Splitter Machine

For global tire recyclers and exporters, shipping “air” inside waste tires is a significant cost drain. The SL-1400 tire splitter machine addresses this logistical challenge by slicing whole tires circumferentially from the center of the tread. This process transforms a bulky, rigid tire into two stackable halves, allowing for efficient nesting.

By utilizing this tire half cutting machine, operators can double the loading quantity of waste tires in standard shipping containers, effectively halving the transportation cost per unit. The SL-1400 is designed to handle a wide range of tire sizes up to 1400mm, making it a versatile asset for handling both PCR (Passenger Car Radial) and TBR (Truck and Bus Radial) tires.

Related

What Is A Tire Splitter?

By utilizing this tire half cutting machine, operators can double the loading quantity of waste tires in standard shipping containers, effectively halving the transportation cost per unit. The SL-1400 is designed to handle a wide range of tire sizes up to 1400mm, making it a versatile asset for handling both PCR (Passenger Car Radial) and TBR (Truck and Bus Radial) tires.

Tire Splitter Technical Specifications

The SL-1400 is built for continuous industrial operation. Unlike lightweight cutters, this unit features a heavy-duty chassis and a specialized dual-motor configuration.

| Parameter | Specification | Technical Insight |

|---|---|---|

| Model | SL-1400 | High-Speed Splitter Series |

| Function | Mid-tread Splitting | Cuts whole tire into 2 pieces |

| Max Tire Diameter | < 1400 mm | Covers nearly all commercial vehicle tires |

| Processing Capacity | 2 – 3 pcs/min | High throughput (120-180 tires/hour) |

| Power System | 4kw + 3kw (380V) | Independent drive and cutting motors |

| Machine Weight | 1200 kg | High mass ensures stability during cutting |

| Dimensions | 185014501500 mm | Compact footprint (approx. 2.7 m²) |

The Advantage of a Dual-Motor Drive System

The SL-1400 distinguishes itself from standard splitters through its 4kw+3kw dual-power architecture.

- Rotational Drive (4kw): The primary motor drives the internal expansion chuck, spinning the tire at high speeds. This centrifugal force keeps the tire rigid, ensuring a clean cut.

- Cutter Drive (3kw): A separate motor or hydraulic station powers the blade feed. This separation of power ensures that the truck tire tread cutter maintains constant pressure even when encountering thick steel belts in heavy-duty truck tires, preventing jamming and motor burnout.