خط إنتاج مسحوق المطاط

كل خط إنتاج مسحوق المطاط يدعم التكوينات المخصصة، مع مراعاة الكفاءة والتكلفة والمعايير البيئية، وتلبية احتياجات جميع السيناريوهات، من إعادة تدوير الإطارات الصغيرة والمتوسطة إلى النطاق الصناعي. تقدم Shuliy حلول إعادة التدوير بما في ذلك النوع شبه الآلي، الخط الكامل الأتمتة-1، الخط الكامل الأتمتة-2، خط إعادة تدوير إطارات OTR القياسي، خط إعادة تدوير إطارات OTR العملاقة.

تعدد المواصفات

تغطية الإطارات بأقطار تتراوح من 300 إلى 4000 مم، يمكن لخط واحد تلبية مختلف الطلبات.

معالجة مسبقة عالية الكفاءة

عملية معيارية (قطع الحلقات / السحب، قطع الشرائط / القطع، التقطيع، فصل الأسلاك الفولاذية / النايلون، الطحن).

مسحوق مطاطي عالي الجودة

شبكة قابلة للتعديل من 10-80، نقاء ≥99.2%، لتلبية مواد أرضيات المدرج، تعديل الأسفلت، المطاط المعاد تدويره، إلخ.

مخصص خط إنتاج مسحوق المطاط لإعادة تدوير الإطارات

خط إنتاج مسحوق المطاط شبه التلقائي

حد استثمار منخفض: مناسب للعمليات الصغيرة، ومناسب بشكل خاص للميزانيات المحدودة أو شركات إعادة التدوير الناشئة لبناء مصنع بسرعة.

ترقية خطوة بخطوة وتوسيع سلس: في البداية، يمكن تكوين وحدات القطع والتمزيق والتقطيع الأساسية فقط، ثم إضافة معدات الفحص وغيرها، لتحقيق تحسين مزدوج في الإنتاجية والجودة.

المعلمات الرئيسية

القدرة اليومية 533_d63890-37> | 1-3 طن في اليوم 533_272b19-41> |

كفاءة فصل الفولاذ والنايلون 533_899c0f-d1> | 99.2% 533_50167b-05> |

حجم مسحوق المطاط 533_c7f19c-ff> | 10-40 شبكة (2.5-0.63 مم) 533_8f3ee2-36> |

قوة المحرك 533_03b0f2-79> | 30-150 كيلو واط (حسب الطراز) 533_2960ef-81> |

المزايا

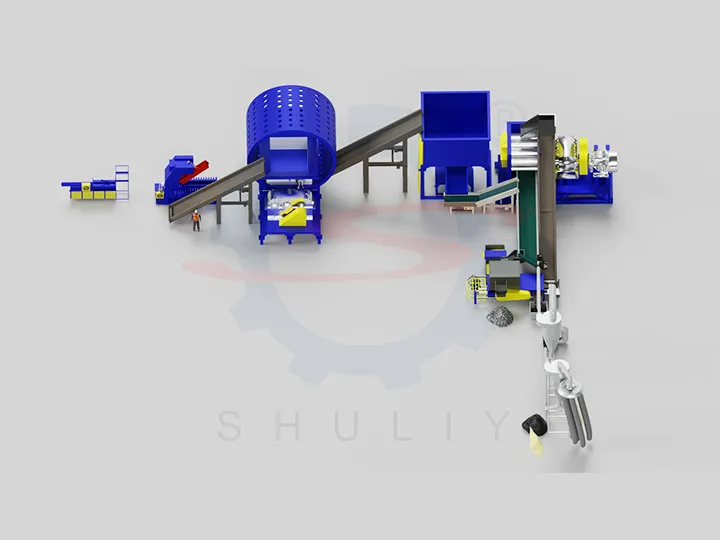

خط إنتاج مسحوق المطاط الأوتوماتيكي بالكامل

أتمتة العملية الكاملة: معالجة أولية – تقطيع – تكسير خشن – تكسير ناعم تصميم متكامل، نقل مواد سلس، تقليل الركود البيني.

تكسير مزدوج المرحلة، إنتاج عالي الكفاءة: يجمع بين عمليتي التكسير، الكسارة الخشنة والكسارة الدقيقة، مما يحقق تكسيرًا سريعًا وطحنًا عميقًا.

تشغيل مستمر: صيانة منخفضة: يضمن نظام التخزين والتفريغ الأوتوماتيكي الإمداد المستمر للمواد.

المعلمات الرئيسية

القدرة اليومية 533_4984b0-f4> | 3-35 طن في اليوم (24 ساعة) 533_9506e5-9a> |

استهلاك الطاقة 533_c1b5de-c5> | ≤ 40 كيلو واط ساعة / طن 533_6d7063-44> |

حجم المسحوق 533_35914b-d0> | 10-80 شبكة 533_c99b9e-11> |

نقاء المسحوق 533_f426d0-82> | 99.2% 533_e26b69-a7> |

المزايا

خط إنتاج مسحوق المطاط الأوتوماتيكي الكامل Ⅱ

متطلبات الحجم: تم تصميم خط إنتاج مسحوق المطاط الآلي بالكامل لدينا لإعادة تدوير إطارات الخردة بكفاءة يصل قطرها إلى 1200 مم.

عملية معالجة أولية مبسطة: يدمج استخدام قاطع الإطارات متعدد الوظائف عملية المعالجة الأولية المعقدة (قطع الجدران الجانبية وقطع الكتل في آلة واحدة)، ويحسن كفاءة المعالجة الأولية للإطارات، ويوفر مساحة المصنع.

المعلمات الرئيسية

القدرة اليومية 533_21994d-2e> | 3-35 طن في اليوم (24 ساعة) 533_9b35f1-1f> |

إجمالي الطاقة 533_58c56f-ef> | 180-220 كيلو واط (حسب التكوين) 533_a84e33-a1> |

حجم المسحوق 533_c24b8f-03> | 10-40 شبكة (شاشات قابلة للتخصيص) 533_433fc3-1a> |

معدل فصل الأسلاك الفولاذية 533_7846ea-4b> | 99.2% أو أكثر 533_7be1b6-2b> |

المزايا

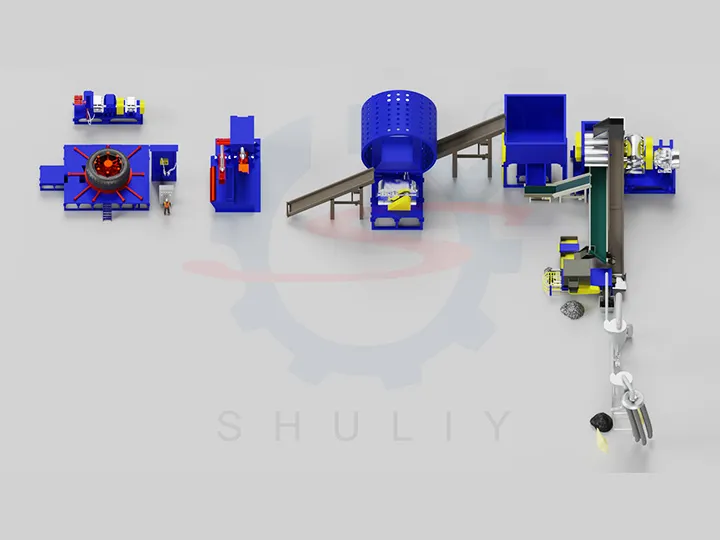

مصنع إعادة تدوير إطارات OTR القياسية

إعادة تدوير الإطارات الكبيرة: تم تصميم خط إعادة التدوير هذا لمعالجة الإطارات الهندسية والتعدينية الكبيرة جدًا التي يتراوح قطرها بين 1400 مم و 4000 مم لصناعات التعدين والبناء والموانئ.

خيارات مخصصة: يتم تقديم حلول مخصصة للإطارات ذات الأحجام والتكوينات المختلفة لضمان سحق فعال وإنتاج مسحوق مطاط عالي النقاء.

المعلمات الرئيسية

القدرة اليومية 533_5470e8-68> | 10-35 طن في اليوم (24 ساعة) 533_3765fd-bc> |

تطبيق 533_744ab8-af> | إطارات الهندسة الكبيرة والتعدين والشاحنات الثقيلة 533_1cf467-fa> |

قطر الإطار 533_3a7bdb-40> | 1400-4000 مم 533_3ce75e-eb> |

حجم المسحوق النهائي 533_d30e69-f8> | 10-80 شبكة 533_fed925-98> |

نظرة عامة على المعدات

العملية الأساسية

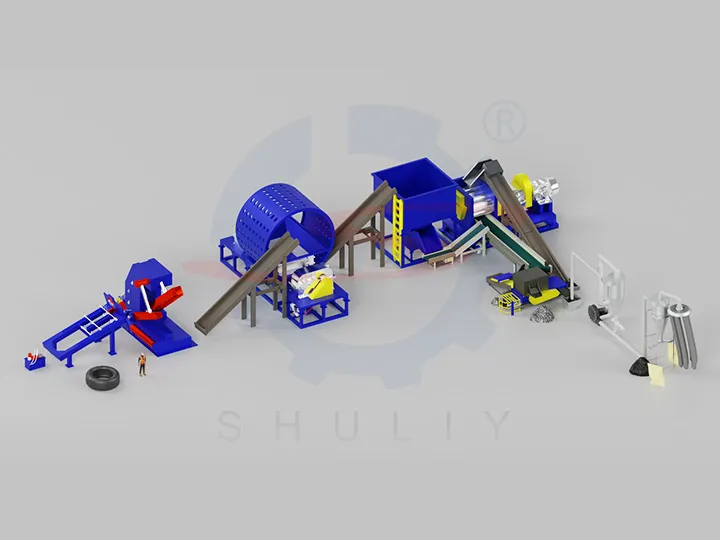

خط معالجة إطارات OTR العملاق

لتلبية الطلب على إعادة تدوير ومعالجة إطارات البناء الكبيرة بقطر 2100 مم وما فوق، نقدم:

تشمل خط معالجة الإطارات جهاز تفكيك الإطارات OTR، قاطع، فاصل الحافة، جهاز تمزيق كبير الحجم، نظام تخزين تلقائي، آلة مسحوق المطاط كبيرة الحجم (XKP450 وما فوق)، فاصل الهواء النايلون ونظام جمع ونقل مسحوق المطاط.

يمكن أن تحقق هذه الحلول العملية الكاملة لمعالجة الإطارات الكبيرة من التفكيك الأولي، والقطع والفصل، إلى تمزيق المطاط، والسحق الدقيق، وفصل النايلون.

المعلمات الرئيسية

القدرة اليومية 533_4d4f6a-de> | 5-20 طن يومياً 533_be9619-3e> |

تطبيق 533_cded56-d6> | إطارات الهندسة الكبيرة والتعدين والشاحنات الثقيلة 533_bd63fa-3e> |

قطر الإطار 533_6db4cf-a1> | أكثر من 2100 مم 533_b04685-92> |

حجم مسحوق المطاط 533_5a878f-3d> | 10-80 شبكة 533_fef2eb-6a> |

نظرة عامة على المعدات

العملية الأساسية

أنواع إطارات نهاية الحياة

مصنع تمزيق الإطارات لدينا قادر على معالجة مجموعة واسعة من الإطارات المستعملة، من المركبات العادية إلى المعدات الصناعية والزراعية. إليك الفئات الرئيسية:

تطبيقات متعددة لمنتجات إعادة تدوير الإطارات.

سلك فولاذي معاد تدويره

تطبيق ألياف النايلون الدقيقة

هل تريد مشروع OTR؟

طورت شركة شولي نظام معالجة آلي بالكامل للإطارات الكبيرة الحجم OTR (بقطر يتراوح بين 1400-4000 مم، و2100 مم + نماذج خاصة متاحة) لمعدات التعدين والبناء، مع دمج تقنيات التقطيع الهيدروليكي، والفصل الذكي للأسلاك، والنقل الآلي.

OTR حلول

نظامك الكامل لتفكيك إطارات OTR العملاقة واستعادة المطاط.

خط إعادة تدوير إطارات OTR القياسي

أقصى قطر معالجة هو 4000 مم

العملية: الرسم → القطع → التقطيع → الطحن → الفصل → الجمع.

خط إعادة تدوير الإطارات العملاقة OTR

أدنى قطر معالجة هو 2100 مم

العملية: تفكيك الإطار الكامل → القطع → فصل الأسلاك → التقطيع → السحق → الفصل → الجمع.

آلة تفكيك

يمكن لجهاز تفكيك الإطارات OTR قطع وفصل إطارات البناء التي يزيد قطرها عن 2100 مم (R35-R63) إلى 4-6 أجزاء مثل فتح الحافة، المداس، وأعلى الإطار.

مستخرج سلك الحافة

فاصل الحافة لفصل أسلاك حافة إطارات البناء من 1400-4000 مم.

آلة إزالة الفولاذ من الإطارات

آلة سحب الأسلاك OTR تقوم بسحب أسلاك حافة إطارات البناء من 1800-4000 مم مباشرة.

الأسئلة الشائعة

قمنا بإدراج عدة أسئلة تهم معظم المجمعين. ألقِ نظرة!