橡胶粉生产线

每条橡胶粉生产线都支持定制配置,充分考虑效率、成本和环保标准,满足从小到大、从中小规模到工业规模的各种轮胎回收场景需求。Shuliy 提供包括 半自动型、全自动线-1、全自动线-2、标准OTR轮胎回收线、巨型OTR轮胎回收线在内的回收解决方案。

多规格

覆盖直径从300到4000毫米的轮胎,一条生产线可以满足各种需求。

高效预处理

模块化工艺(环切割/拉伸、条切割/切割、粉碎、钢丝/尼龙分离、研磨)。

高质量橡胶粉

10-80目可调,纯度≥99.2%,满足跑道地面材料、沥青改性、再生橡胶等要求

定制 橡胶粉生产线 轮胎回收

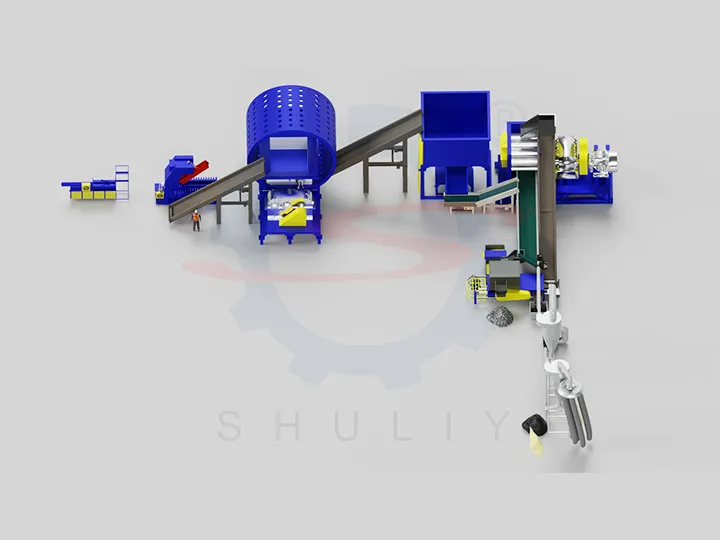

半自动橡胶粉生产线

投资门槛低:适合小规模运营,尤其适合预算有限或初创回收商快速建厂。

分步升级,平滑扩展:初期可仅配置核心的切边、破碎、切粒模块,后续再增加筛分等设备,实现产能和质量的双重提升。

关键参数

每日产能 533_d63890-37> | 每天1-3吨 533_272b19-41> |

钢尼龙分离效率 533_899c0f-d1> | 99.2% 533_50167b-05> |

胶粉粒度 533_c7f19c-ff> | 10-40目(2.5-0.63毫米) 533_8f3ee2-36> |

电机功率 533_03b0f2-79> | 30–150千瓦(根据型号而定) 533_2960ef-81> |

优点

全自动橡胶粉生产线

全流程自动化:预处理-切边-粗破-细破一体化设计,物料输送顺畅,减少中间滞留。

双段破碎,高效出料:结合粗破和细破两大破碎工序,实现快速破碎与深度研磨。

连续运行,低维护:自动储料和出料系统保证物料的连续供应。

关键参数

每日产能 533_4984b0-f4> | 每天3-35吨(24小时) 533_9506e5-9a> |

能耗 533_c1b5de-c5> | ≤ 40 kWh/吨 533_6d7063-44> |

粉末大小 533_35914b-d0> | 10-80目 533_c99b9e-11> |

粉末纯度 533_f426d0-82> | 99.2% 533_e26b69-a7> |

优点

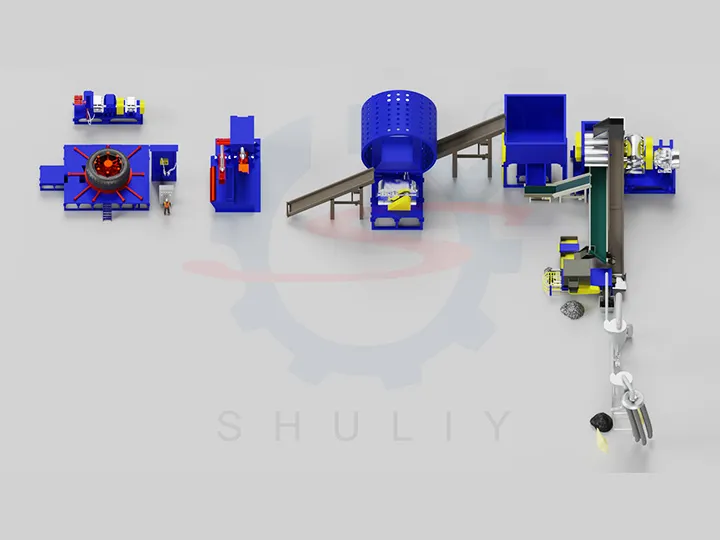

全自动橡胶粉生产线Ⅱ

尺寸要求: 我们的全自动橡胶粉生产线设计用于有效回收直径高达1200mm的废旧轮胎。

简化预处理过程:使用多功能轮胎切割机将繁琐的预处理过程(侧壁切割和块切割合为一机),提高轮胎的预处理效率,节省厂房面积。

关键参数

每日产能 533_21994d-2e> | 每天3-35吨(24小时) 533_9b35f1-1f> |

总功率 533_58c56f-ef> | 180-220千瓦(根据配置而定) 533_a84e33-a1> |

粉末大小 533_c24b8f-03> | 10-40目(可定制筛网) 533_433fc3-1a> |

钢丝分离率 533_7846ea-4b> | 99.2%或以上 533_7be1b6-2b> |

优点

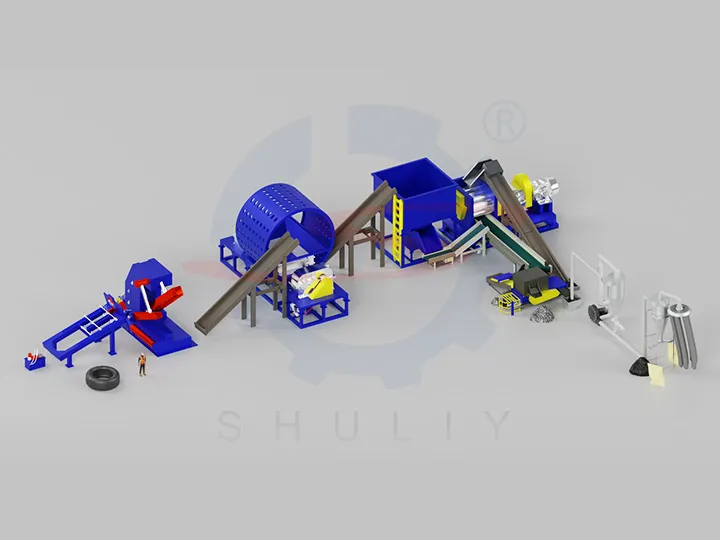

标准OTR轮胎回收工厂

大尺寸轮胎回收:该回收线设计用于处理直径在1400mm到4000mm之间的超大工程和矿山轮胎,适用于矿业、建筑和港口行业。

定制选项:为不同尺寸和配置的轮胎提供定制解决方案,以确保高效破碎和高纯度橡胶粉的输出。

关键参数

每日产能 533_5470e8-68> | 每天10-35吨(24小时) 533_3765fd-bc> |

应用 533_744ab8-af> | 大型工程、矿业和重型卡车轮胎 533_1cf467-fa> |

轮胎直径 533_3a7bdb-40> | 1400-4000 毫米 533_3ce75e-eb> |

最终粉末尺寸 533_d30e69-f8> | 10-80目 533_fed925-98> |

设备概述

核心流程

巨型OTR轮胎处理线

对于直径2100mm及以上的大型建筑轮胎的回收和处理需求,我们提供:

轮胎加工线包括OTR粉碎机、切割机、轮辋分离器、大型撕碎机、自动存储系统、大型橡胶粉碎机(XKP450及以上)、尼龙气体分离器和橡胶粉收集与运输系统。

该解决方案可以实现从初始拆解、切割和分离超大轮胎的整个处理过程,包括橡胶粉碎、细碎和尼龙分离。

关键参数

每日产能 533_4d4f6a-de> | 每天 5-20 吨 533_be9619-3e> |

应用 533_cded56-d6> | 大型工程、矿业和重型卡车轮胎 533_bd63fa-3e> |

轮胎直径 533_6db4cf-a1> | 超过2100毫米 533_b04685-92> |

橡胶粉末尺寸 533_5a878f-3d> | 10-80目 533_fef2eb-6a> |

设备概述

核心流程

废旧轮胎的类型

我们的轮胎粉碎机工厂能够处理各种废旧轮胎,从日常乘用车到工业和农业设备。以下是主要类别:

轮胎回收副产品的多种应用。

回收钢丝

优质尼龙纤维应用

想要一个OTR项目吗?

Shuliy开发了一种针对超大轮胎(直径1400-4000mm,2100mm及特殊型号可用)的全自动处理系统,适用于矿业和建筑机械,集成了液压破碎、智能线缆分离和自动输送。

OTR 解决方案

您的完整系统,用于巨型轮胎破碎与橡胶回收。

常见问题

我们列出了许多回收商感兴趣的问题。来看看吧!